What We Can Customize for Your Plastic Caps?

- PP or PP+TPR

- 24mm, 28mm, 33mm, 38mm, 43mm, 45mm, 48mm, 53mm, 58mm, 63mm, 70mm, 83mm, 89mm, 100mm, 110mm, 120mm

- Custom diameter available

- 400, 485, 490

- White, black, natural, blue, red, yellow, or custom

- Screw-on, snap-on, child-resistant, or custom closure types

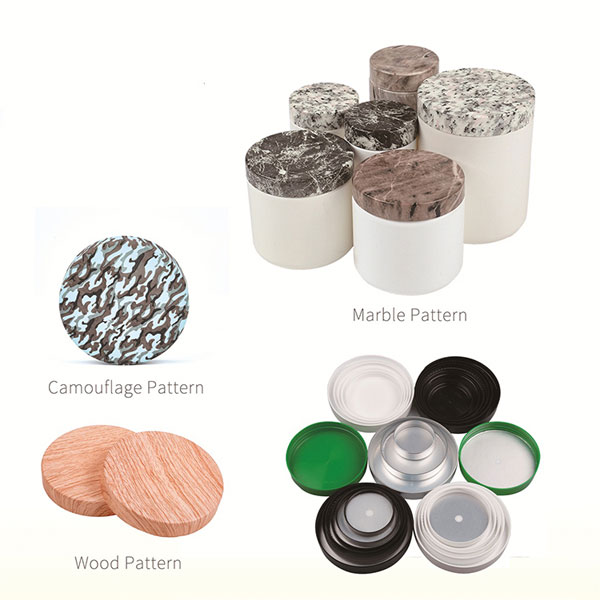

- Plain, marble, camouflage, wood

- Custom available

- Foam, pressure-sensitive, induction, lift-and-peel, heat-seal, venting

Typical Size and Neck Finish

Item Number | Resin | Diameter (mm) | Neck Finish |

PP-Cap-24 | PP | 24 mm | 400, 485, 490 |

PP-Cap-28 | PP | 28 mm | 400, 485, 490 |

PP-Cap-38 | PP | 38 mm | 400, 485, 490 |

PP-Cap-48 | PP | 48 mm | 400, 485, 490 |

PP-Cap-58 | PP | 58 mm | 400, 485, 490 |

PP-Cap-63 | PP | 63 mm | 400, 485, 490 |

PP-Cap-70 | PP | 70 mm | 400, 485, 490 |

PP-Cap-89 | PP | 89 mm | 400, 485, 490 |

PP-Cap-120 | PP | 120 mm | 400, 485, 490 |

Liner Options

Cap liners are essential components of bottle caps and closures. There are various types of cap liners available, each suited for specific applications.

PE Foam Liner

Made from low-density polyethylene (LDPE) foam and are commonly used for sealing dry products, powders, and liquids. They create a strong seal against the container, providing excellent moisture resistance.

Pressure Sensitive Liner

Pressure-sensitive liners (PS liners) consist of foam or paper backing coated with a pressure-sensitive adhesive. When the cap is screwed onto the container, the liner adheres to the container's rim.

Induction Seal Liner

The cap liner is heated by electromagnetic induction, creating a hermetic seal between the cap and the container. These liners are commonly found in products like pharmaceuticals, food, and beverages.

Venting Liner

Venting liners are designed to allow pressure equalization. They are often used in applications where the packaged product may experience pressure changes, such as with chemicals or volatile substances.